Handling, flipping and safely mounting 600mm build platforms has quickly evolved into a time killer and safety issue many shops didn’t see coming with the break through of larger metal AM printers from Velo3D and SLM in recent years. Working with our customers EDM Performance Accessories has designed, tested and built a fixture specifically for these large plates to increase efficiency and safety during the cut off process.

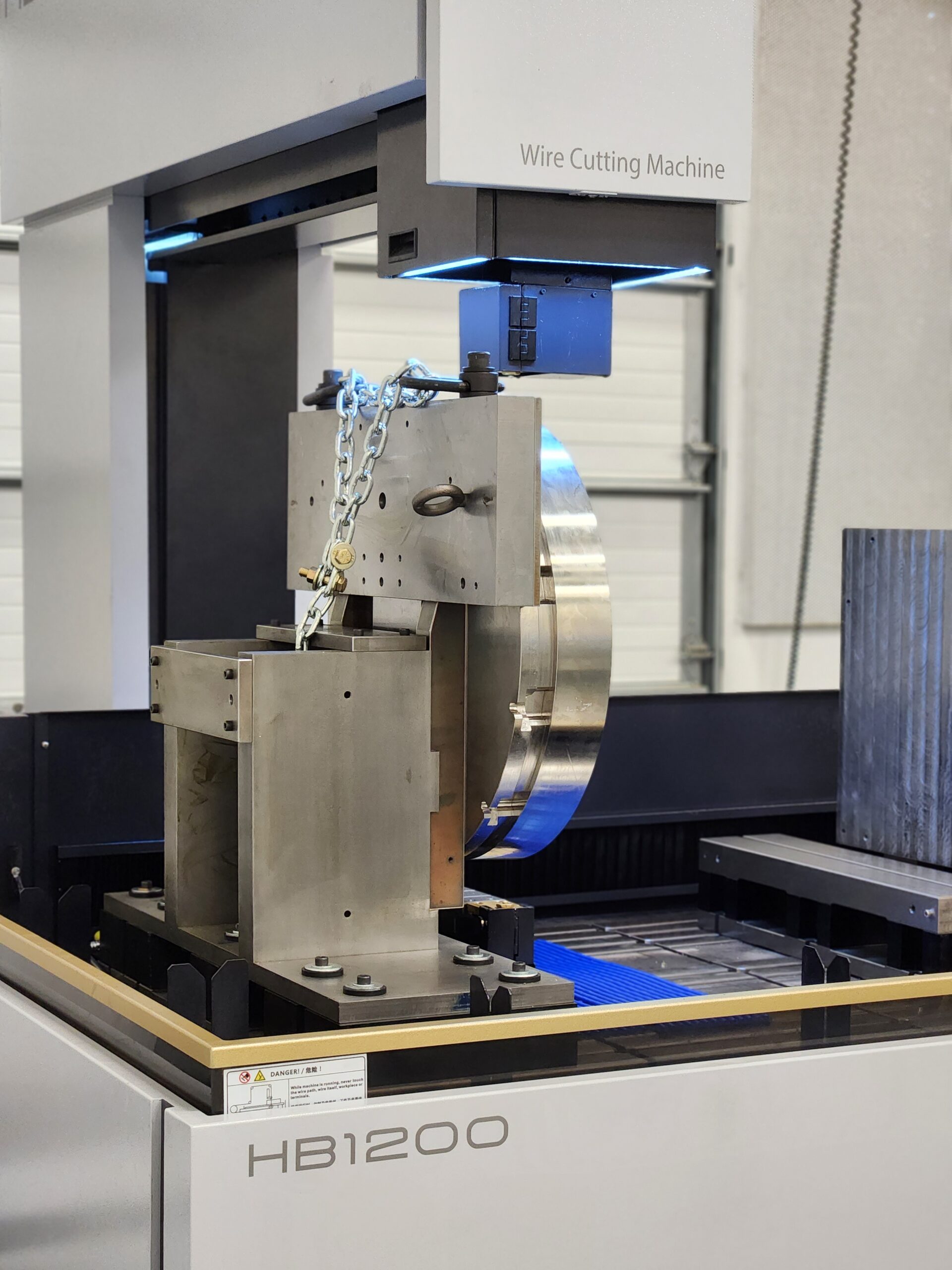

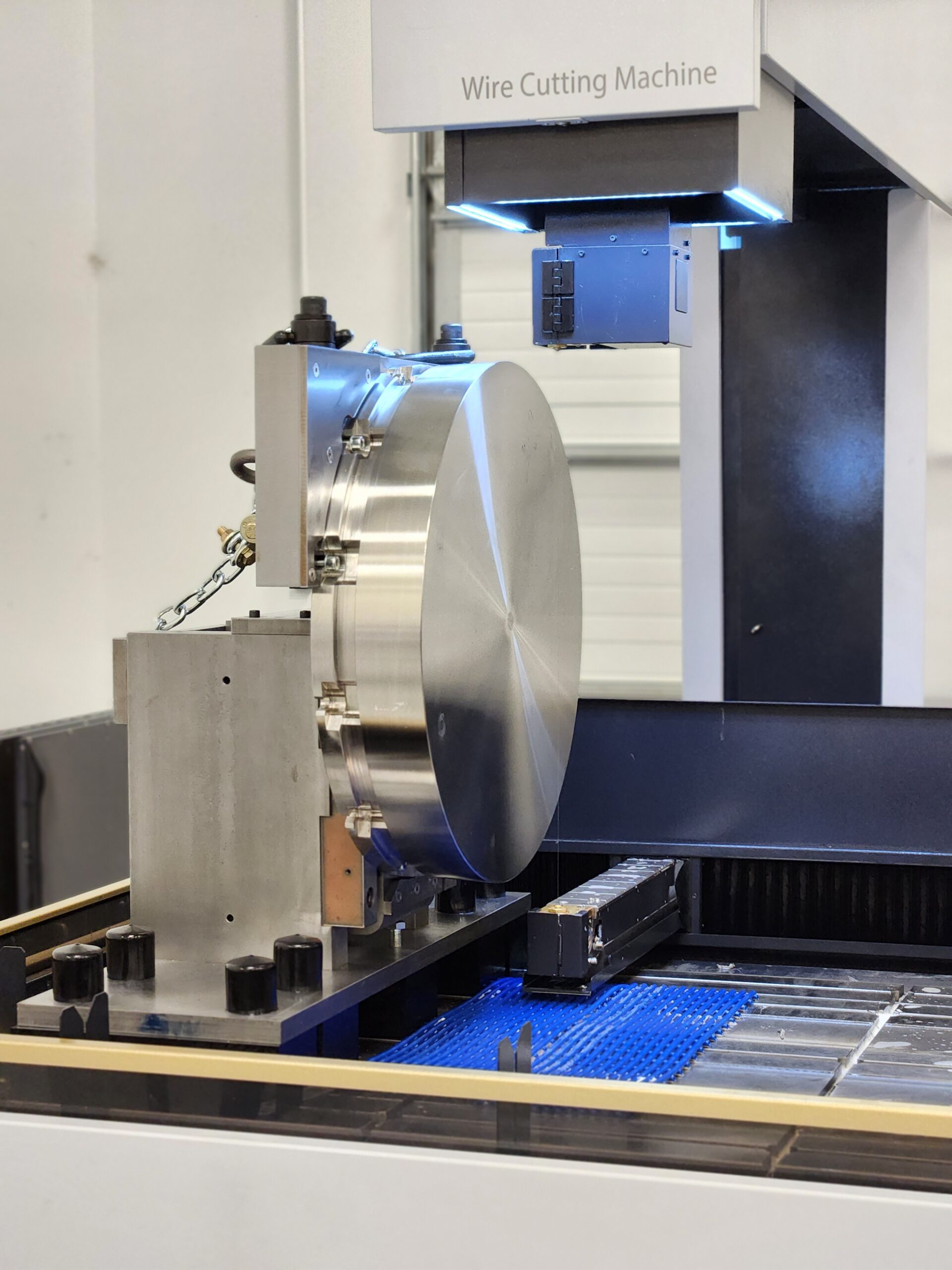

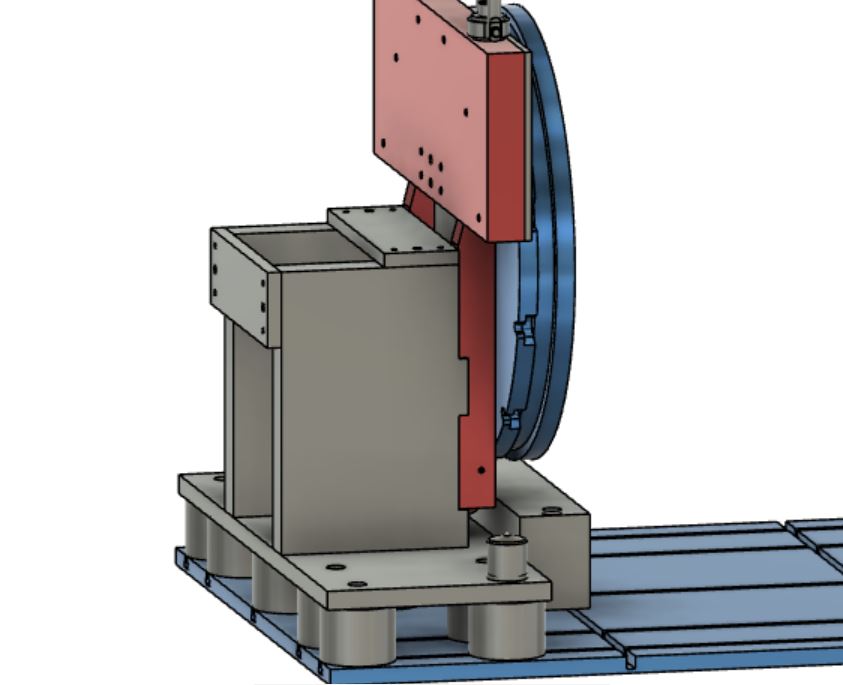

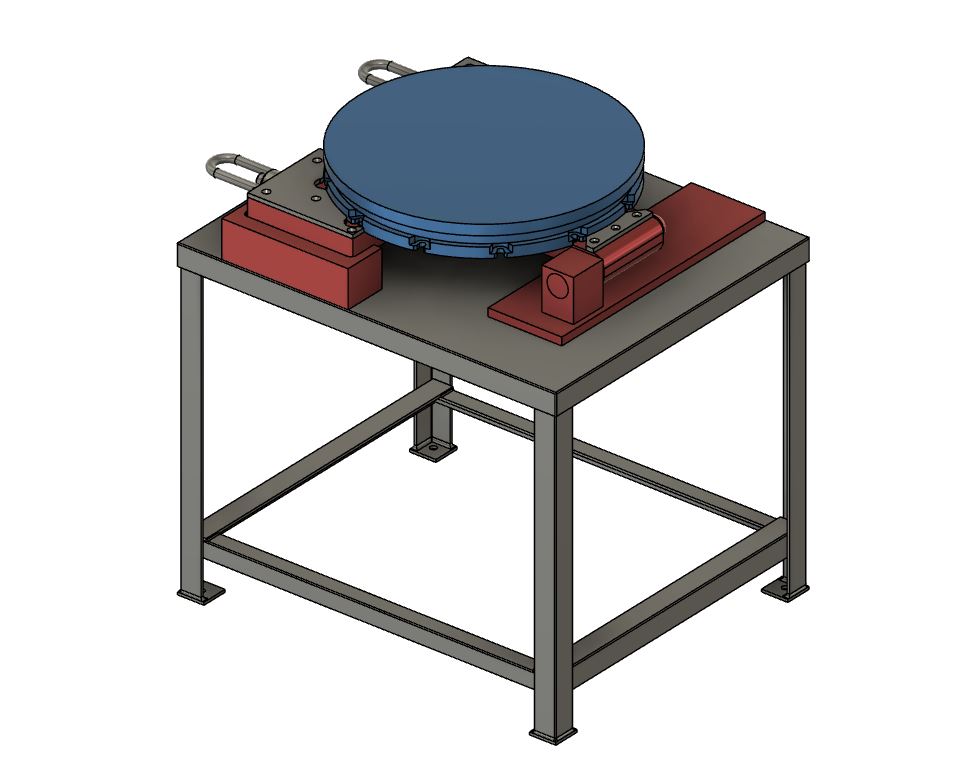

The fixture consists of 3 main parts. The Pivot Table, Sub-Fixture, and Machine Fixture. These parts all work together to properly hold and control these heavy build platforms during the cut off process. Coming it at over 600lbs of steel all machined and precision ground this fixture means business and is designed to handle the heavy massive parts these printers and produce!

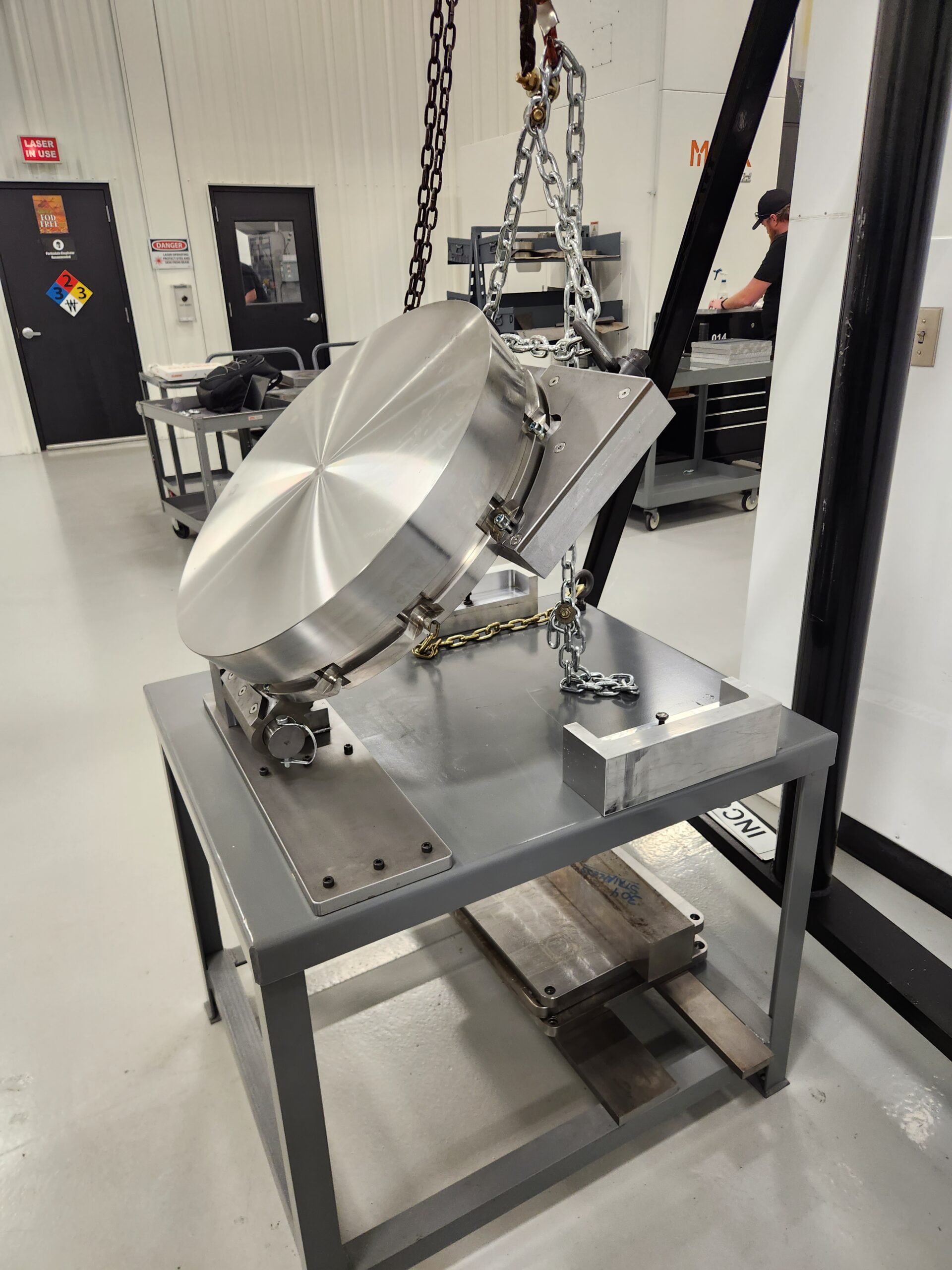

Starting with the Pivot Table. Built on a 10,000lb capacity steel assembly table. Mounted on top is 3 leveling pads. The top 2 pads level and support the sub-fixture, the bottom pad contains a leveling bolt and the pivot pin which engages with the sub-fixture. The pivot pin is a solid 2” diameter precision shaft solidly mounted to the base plate. Lastly the table has a 4,800lb safety chain to support the sub fixture during the flipping process. If the load becomes forward heavy un-expectedly, the chain will catch it not allowing it only about 5 degrees past 90.

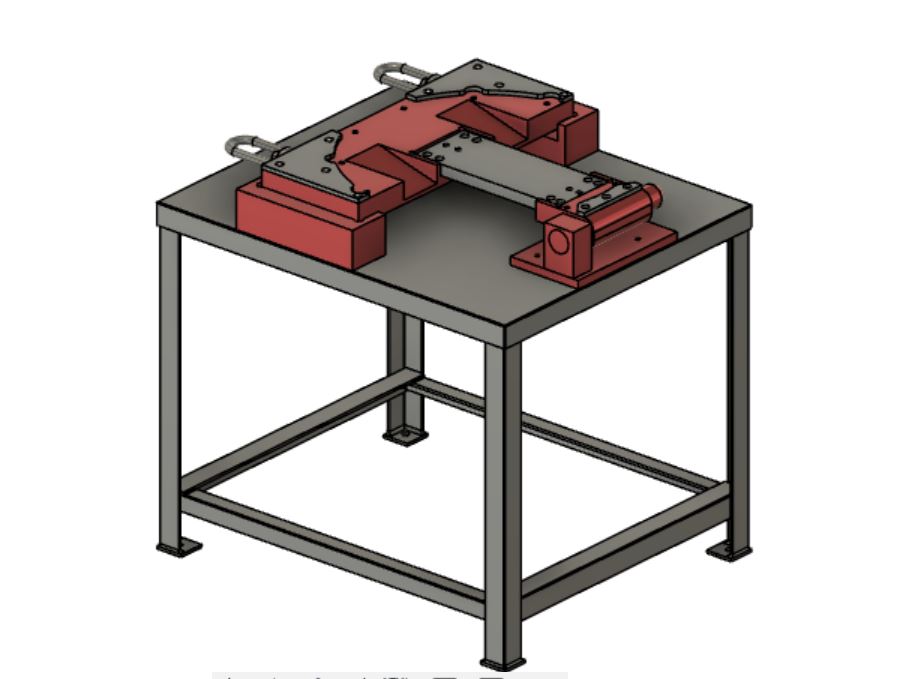

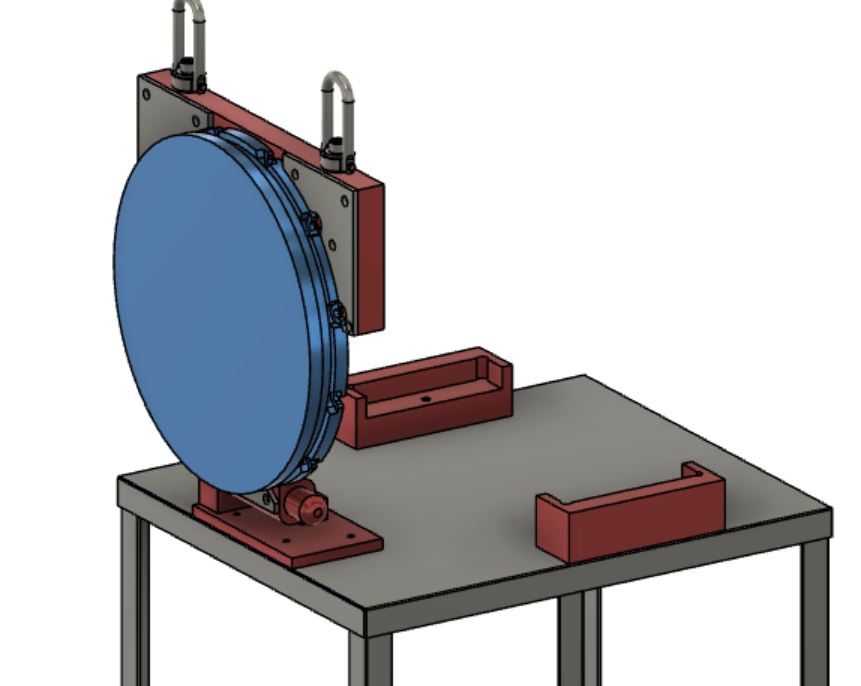

The Sub-Fixture was designed to be both highly ridged and modifiable depending on if the fixture is being used for VeloXC or NXG600 plates, or both! This sub-fixture has a couple important jobs. First it allows easy flat mounting and alignment of the build plate and has pre-drilled and taped mounting holes to secure the build in position. It features alignment guides that get the plate within .100” of its intended position for mounting. Second the Sub-fixture is what engages the pivot table to allow a safe and controlled flip to a vertical position. Once balanced and vertical the entire assembly will simply lift off the pivot pin once the safety pins are removed. Lastly the Sub-Fixture features our innovative wedge long lock technology. This allows the Sub-Fixture to simply be lowered onto the machine mounting base, pull itself in and self-align. No bolts or machine alignment required and the operator never need to engage with the heavy moving parts!

The last piece to our 600mm Build Plate Fixturing System is the machine mount. This innovative mount has the receiving posts for our taper lock technology. Mounting a 1000lb+ plate is now safer and easier than ever. Visual alignment is all that is needed to get the Sub-Fixture to engage and then simply lower the Sub-Fixture into the table lock. Operators never need to be in the machine or in danger trying to mount these heavy parts. Once finished the plate can released from the taper with a M14 bolt directly below the fixture and then simply lifted out.

To learn more or talk to one of our tooling specialist reach out our support team below (Add Link to “Contact Us” page)

To learn more or talk to one of our tooling specialist reach out our support team below.